On Dec. 8, Hailiang Non-ferrous Industrial Park project held a grand starting ceremony in Zhuji Modern Environmental Protection Equipment High-Tech Industrial Park. The project that adopts Hailiang's independent patent R&D technology with the advantages of automation, intelligence, environmental protection and low energy consumption is of an international leading level, marking Hailiang's upgrading from traditional manufacturing to intelligent manufacturing. Such a project is of positive significance to boost Zhejiang Non-ferrous Metal Processing Industry to develop in the direction of green, intensity, intelligence, high-end and internationalization.

Weiguang Ma, Secretary of the Shaoxing Municipal Party Committee, attended the ceremony and announced the start of the project. Guolong Xu, Wei Lu, Liangping Xu, Fenxiang Wang, Hansong Yao, Haoliang Guo, Fangle Xuan, Guofeng Meng, Hongwei Zhu and other officials from Shaoxing and Zhuji government departments and Hailiang Feng, Yali Feng, Jianguo Cao, Zhangquan Zhu and other senior managers from Hailiang Group all attended the ceremony.

Application of Hailiang's independent patent R&D technology – Upgrading from conventional manufacturing to intelligent manufacturing

Hailiang Nonferrous Industrial Park covers an total area of 100 mu with a total investment of 6.128 billion yuan. The park will be implemented in three phases according to the project layout: the first phase of the project will be “intelligent energy-saving emission reduction and land expansion project with an annual output of 400,000 tons of copper and copper alloy bar”, which is expected to be completed and delivered in December 2019; the second phase of “precision aluminum construction project with an annual output of 150,000 yuan” is due to be completed and delivered in June 2021; and the third phase that plans to build “up-down stream extension project and innovative experimental platform construction project in the field of non-ferrous metal processing” is estimated to be completed before December 2022.

After being fully completed, the production line of the park is expected to reach an international leading level with the equipment enjoying favorable conditions of automation, intelligence, low energy consumption, etc., the process possessing the advantages of cleanness, short procedure and intelligent control technology, etc. and the products exhibiting strengths in precision, environmental protection and zero defects. Such project is in line with the development strategy and low energy consumption requirements of the national non-ferrous metal processing industry.

“The construction of Hailiang Non-ferrous Smart Industrial Park is a solid step for us to realize our corporate vision of becoming a giant in the global non-ferrous materials smart manufacturing,” Zhangquan Zhu remarked at the opening ceremony. The project that goes beyond the product and application ends to upgrade from traditional manufacturing to intelligent manufacturing is a major strategic project of Hailiang Group.

Expansion of clients – Striving for a dominant position in the industry

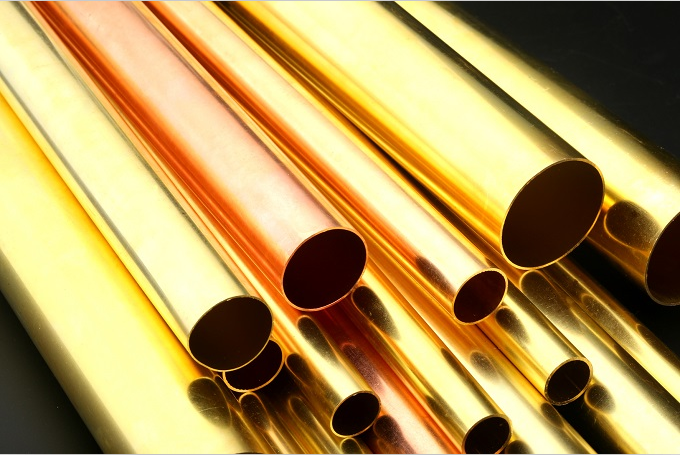

Judging from the features of copper processing industry, the most remarkable value of upgrading from traditional manufacturing to smart manufacturing is to quickly take a dominant position by building a new intelligent production line with the latest equipment and technology. The production of high-level, precise and cutting-edge products by hand such as precise copper rods used in aeronautics and astronautics, precise alloy rods used in automobile manufacturing, heat exchange copper alloy tubes, large-caliber white copper tubes for naval vessels and copper fittings for electronic communications is challenging for quality management. Therefore, the automation of copper processing industry is imperative while intelligent manufacturing proves to be an effective approach to ensure product quality.

Recent years of hard work witnessed Hailiang Group’s initial success in using robots rather than human labor to manufacture the key parts of copper pipes and copper rods. Hailiang Non-ferrous Materials Smart Manufacturing Park, upgraded on this base, will not only significantly improve product quality, boost production efficiency, reduce product cost, lower energy consumption, and improve environmental quality, but also eliminate backward production capacity of the industry and accelerate industrial upgrading. Such an endeavor is more beneficial to the sound development of the industry and exerts a very positive impact on the energy conservation and emission reduction of the society.

Apart from the production process, the value of “intelligence” is also reflected in the application of products. After the completion of the project, Hailiang Group's non-ferrous materials manufacturing industry will benefit more customers. Specifically, while retaining its original customers, Hailiang’s products will also benefits customers in communications, automobiles, home appliances, gas cookers, plumbing and sanitary ware, valves and other industries.

Development promotion of related industries -- Driving the industrial process in Shaoxing

At present, Hailiang Group's non-ferrous materials manufacturing industry has a total asset of 20 billion yuan and a net asset of 7.907 billion yuan. More than 7,100 employees are hired and an operating income of 29.816 billion yuan was realized in 2017. Under the guidance of achieving “l(fā)eap-forward development of non-ferrous materials smart manufacturing” recently, Hailiang Group has strategically planned its own copper processing industry growth on a global scale focusing on the development strategy of “2025 non-ferrous materials smart manufacturing”. As a consequence, production bases in ten domestic and foreign regions such as Zhejiang, Shanghai, Anhui, Guangdong, Chengdu, Vietnam, Thailand, and the United States are established.

Non-ferrous metal processing based on copper processing is the fist and advantageous industry in Zhuji. Featuring a good start, solid foundation and rapid development, non-ferrous metal processing enjoys a high reputation in the industry. As copper processing is its earliest focus, Hailiang Group has been devoted to copper processing and become a benchmark enterprise for fine management of such industry. Furthermore, being a model enterprise for the transformation and upgrading of a traditional manufacturing industry, it has maintained its leading profit growth ability for many consecutive years and made great contributions to developing and strengthening the metal processing industry in Zhuji. The completion of Hailiang Park will play a vital role in driving the sustainable, rapid and sound development of relevant industries and the economy in Zhuji.